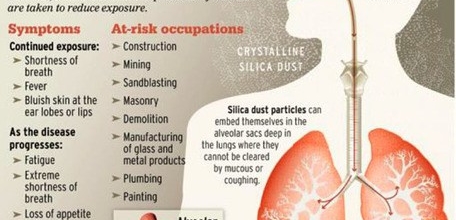

Osha’s new ruling concerning dust emitted during the small batch mixing process is being implemented this month. The primary concern is the prevention of silicosis in workers. You will see a number of new products to address this issue. They are hoods and bonnets that cover the mixing vessel, usually a five gallon pail, attached to a vacuum to collect the dust.

Watch a video from the U.S. Department of Labor showcasing laborers, construction veterans and their families that have been affected by silicosis. #StopSilicosis

We feel that this is the first new rule OSHA has produced regarding small batch mixing. The next obvious regulation will be the stability and safety of the person doing the mixing. No more one or two feet on the pail. No second laborer kneeling next to the pail holding it in place and no more trying to hold the pail between the person’s mixing feet. All of these methods are unsafe and inefficient.

B3 Innovations has patented products that can improve safety and efficiency for small batch mixing:

Bucket Brackets™, Bucket Brackets™ II, and the Bucket Scraper™ eliminate wobbling, spinning buckets and early back fatigue.

Any company or contractor doing small batch mixing will benefit by using the brackets and scraper. They are an essential add on sale for every customer doing small batch mixing.

Learn more about the Silica rule by visiting: www.osha.gov/silica

Review OSHA’s published fact sheet pertaining to the Crystalline Silica Rule for Construction: bit.ly/1VTjBR6

Download OSHA’s Small Entity Compliance Guide for the New Silica Rule for Construction: bit.ly/2fW7dPJ

(315) 243-9614

(315) 243-9614